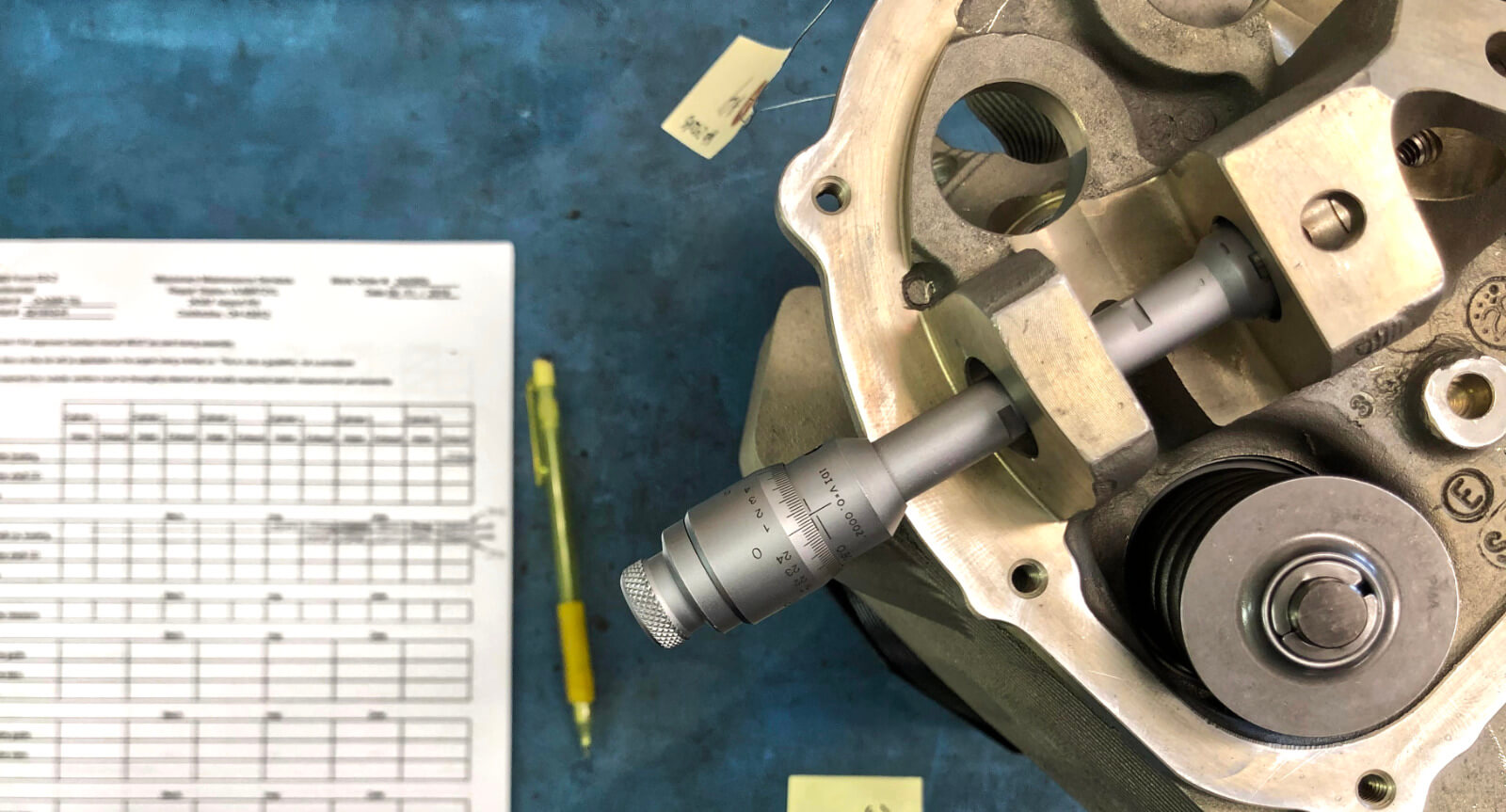

Dimensional inspections are an important part of an engine overhaul. When a mechanic puts together an engine, it’s his (or her) responsibility to make sure the parts he’s putting together are serviceable. The parts must not be too loose or too tight. Let’s say you want to install connecting rods onto the crankshaft. First you must make sure they’re not worn too much or machined too tightly. This means you must get a micrometer and measure the diameter of the crankshaft and compare that to the inside diameter of the connecting rod bearing. Typically you must measure accurately to .0001 of an inch. Then you compare that difference to the Table of Limits where you’ll typically find two standards: New and Serviceable. To complete an engine rebuild, all your parts must measure within the new limits. This is a tighter tolerance. If you are performing an overhaul, your parts must not exceed the serviceable wear limit. Serviceable limits are not as stringent but still perfectly safe and functional. Right now I’m performing an overhaul so all my parts must be serviceable. In reality, almost every single measurement falls within new limits so this engine has better tolerances than required.

That’s just a little window into the world I’m living in right now. Thanks y’all for all your prayers and financial support as we help save mission organizations money now, and prepare and train for where God is calling us next!

Leave a Reply